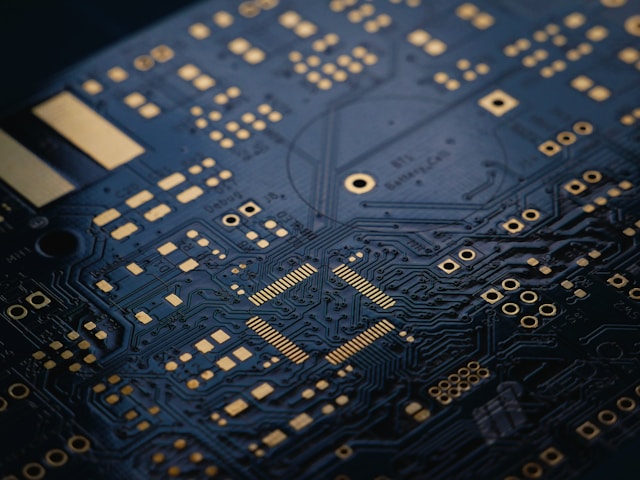

Expert PCB Engineers at a Leading PCB Manufacturing Company in Kochi, Kerala, India Design & Prototype Services

At the core of every functional electronic device is its Printed Circuit Board (PCB). Our comprehensive PCB design and manufacturing services cover every process stage from initial concept through final production.

Precision PCB Design for Complex Systems

A PCB is more than a simple platform for mounting components; it serves as the nerve center of electronic devices. A properly executed design ensures signal integrity, power distribution efficiency, thermal management and electromagnetic compatibility - all essential factors when manufacturing any electronic device.

Our professional circuit board design services mitigate risks by employing industry best practices and cutting-edge design tools to mitigate errors during circuit board design phase and ensure high performance results from manufacturing processes.

Comprehensive Suite of PCB Services

We offer a complete suite of services designed to meet all of your PCB requirements

Custom PCB Designing

Precision engineering for optimal performance

Whilst schematic capture and layout design tailored specifically to meet your specifications.

Efficient PCB Assembly

Advanced assembly with quality components

Automated and manual assembly options to suit varying complexities and volumes

Rapid Electronic Prototyping

Accelerated development cycle

For faster product development. Our quick PCB prototype services will speed up the development cycle.

Full-Scale Manufacturing Support

From prototype to mass production

Attentiveness to every detail ensures a smooth transition from PCB prototype to mass production.

Design for Manufacturability

At our core philosophy is Design for Manufacturability (DFM). DFM is more than a checklist; it is an integral component of our PCB design process and ensures manufacturing constraints and optimization opportunities from early design stages are considered and taken advantage of to maximize manufacturing costs, improve yield rates and ensure success for our customers.

Production Efficiency Enhancement

Designs optimized for automated assembly lead to faster production times and increased efficiencies. Our PCB designs are less vulnerable to manufacturing defects and field failures.

Scalability for Mass Production

Designs are specifically optimized to scale efficiently to meet high-volume demands.

Ready to Bring Your Electronic Vision to Life?

Our team of expert PCB engineers and designers are ready to help you turn your concept into reality with precision and efficiency.