Industrial Data

Acquisition System

A cutting-edge industrial monitoring solution designed to capture actual signals & transform them into dependable, actionable digital data. Built for uninterrupted operation in mission pivotal environments.

What is IDAS?

IDAS is a modular data acquisition and monitoring platform that collects, processes, & transmits data from multiple sensors and field devices. It functions both as a standalone monitoring system and as a fully connected industrial platform.

The system processes data locally at the edge and safely transmits it to servers or cloud platforms for visualization, analytics, reporting, and alarm management. This enables live monitoring, predictive maintenance, and informed decision making throughout industrial operations.

Accurate Measurement & Monitoring of:

System Architecture

Designed for Reliability

Built for continuous operation in harsh industrial environments. Our hardware ensures data integrity with built-in battery backups and independent operation capabilities, meaning your data is safe even during power or network failures.

How IDAS Works

From signal capture to actionable intelligence in 4 simple steps.

Sensor Layer

Sensors are connected to Base Units that acquire analog and digital signals from field devices such as temperature probes, pressure transmitters, vibration sensors, and flow meters.

Local Aggregation

Base Units communicate with Hub Units using wired or wireless communication. Each Hub aggregates and organizes data from multiple Base Units to ensure structured data flow.

Central Comms

The Gateway connects multiple Hub Units and acts as the main communication bridge to servers or cloud platforms using Wi Fi, Ethernet, or SIM based connectivity.

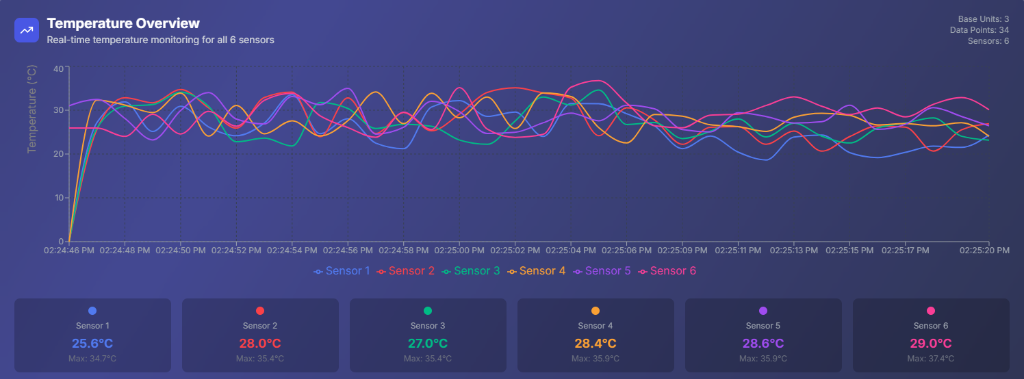

Visualization

Operators access dashboards, alerts, logs, and reports to observe system health, detect oddities, & take proactive action.

Base Unit

Signal Acquisition

- Supports up to 6 sensors

- Analog sensor compatibility

- Wi-Fi communication

- Low power consumption (~5W)

Hub Unit

Local Aggregation

- Connects up to 8 Base Units

- Wi-Fi & RS-485 comms

- Battery backup: 30m - 1 hr

- Industrial grade design

Gateway

Central Intelligence

- Supports up to 28 Hub Units

- Wi-Fi, Ethernet, SIM connectivity

- Onboard storage: 15 GB

- Battery backup: 1 - 2 hours

- High performance (~20W)

Complete Visibility. Absolute Control.

The IDAS Controller acts as the brain of your cold chain operations testing. Monitor unlimited base units and sensors from a single pane of glass, ensuring that every critical parameter is within safe limits.

Monitoring & Control Applications

IDAS supports a wide range of operational, safety, and security applications.

Security & Access Control

- Intruder detection

- Restricted area & time-based access

- Door access monitoring

- Bank vault & locker security

Facility Supervising

- Generator monitoring (power, fuel)

- Water supply (pump health, levels)

- Elevator emergency alarms

- Premises open/close schedules

Safety & Compliance

- Fire alarm system monitoring

- Freezer/Cold storage alarms

- Temperature compliance

Workforce & Occupancy

- Security guard attendance

- Staff presence checking

Healthcare

- Elderly health monitoring

- Emergency alerts & rapid response

Industry Use Cases

Key Features

- Plug and play deployment

- Multi-sensor support

- Wi-Fi, Ethernet, SIM connectivity

- Built-in battery backup

- Real-time alarms

- Edge-level processing

- Independent operation during failures

- Wide compatibility

Why Choose IDAS?

-

Reliable Operation

Built for harsh industrial environments and long-term use.

-

Expandable Architecture

Scales effortlessly from small to large deployments.

-

Uninterrupted Power

Ensures data availability even during power or network failures.

Future Ready Industrial Platform

IDAS is built to assist progressing industrial standards, digital transformation, and data-driven operations. A trustworthy groundwork for advanced automation.

Ensure Cold Chain Confidence with IDAS

Robust, reliable, and ready to protect your most sensitive assets. Join leading pharmaceutical providers in securing their cold chain integrity.